To identify high-quality PE pipes and inferior PE pipes, the following methods can be taken:

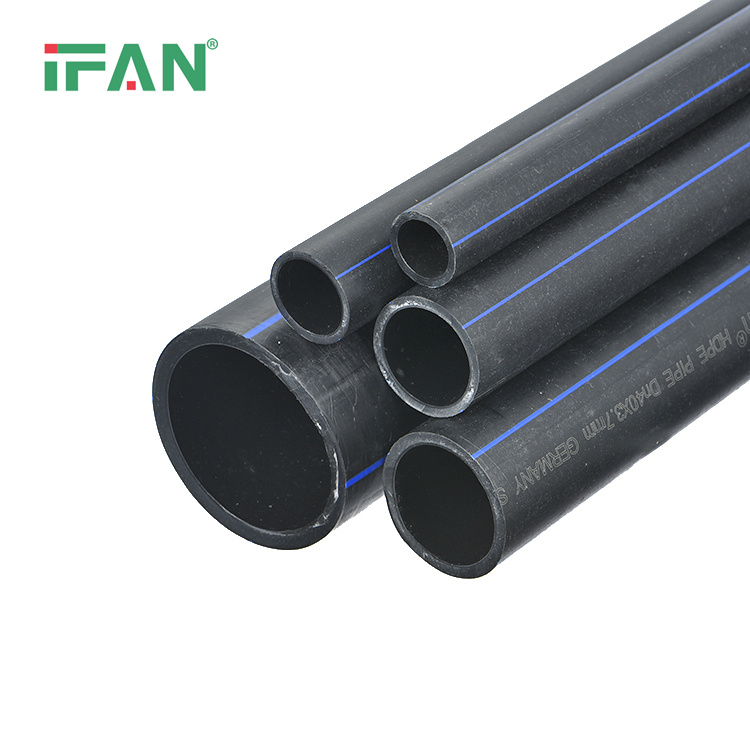

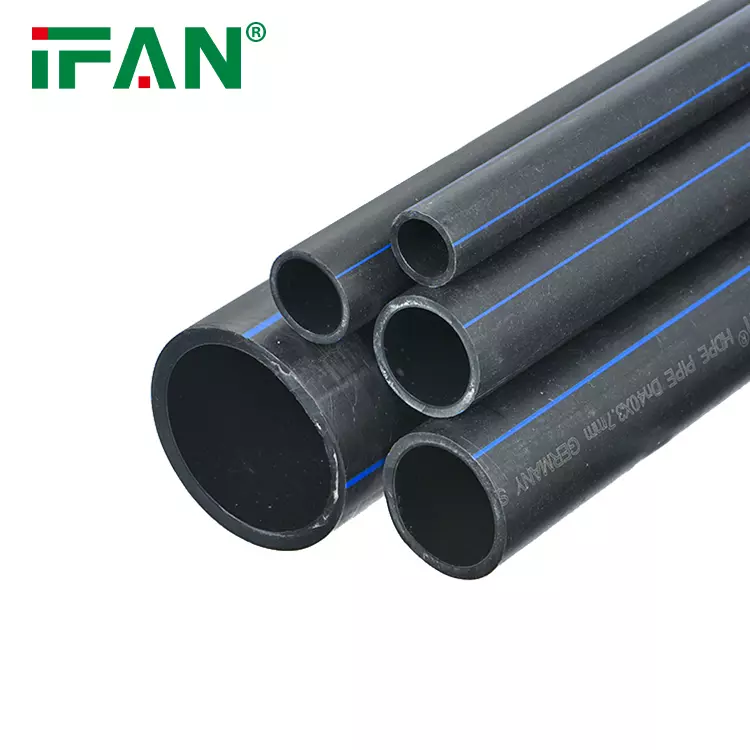

Look at the appearance

The inner and outer surfaces of good pipes are smooth and smooth without bubbles, dents, impurities and other defects. The inner and outer surfaces of the poor pipes are not smooth and bright. And the inner and outer surfaces are obviously dented.

Depending on wall thickness

A good tube has a uniform wall thickness at every point. Some of the poor pipe wall uneven phenomenon is more obvious due to the poor extrusion equipment.

See the ups and downs

Normal PE pipe density is slightly less than the density of water, generally suspended or floating in water. If more fillers are added (such as calcium powder, etc.), it will sink.

See weld

Good pipes are flanged uniformly and tightly without porosity during hot melting. If add some recycled materials to the pipe or the water content of the raw materials used exceeds the standard. The welding flanging will produce pores.

Olfactory discrimination

Freshly processed or hot melted products have a slight plastic smell, and cooled products have no odor. Poor pipes have a pungent smell.

Combustion flame determination

High quality PE tube combustion melt drop stability, flame base is light blue, no odor. The poor quality pipe has a small amount of black smoke and odor due to unstable combustion and irregular melting.

Elongation at break

Elongation at break refers to the ratio of the length value of the specimen at the time of breaking to the original length. The higher the elongation at break, the better the flexibility of the product and the better the performance. The good tube is stretched to 3.5 times without breaking. The poor elongation of the pipe is easy to break and the toughness is poor.

Pressure test

The new material pipe can withstand 1.5 times the pressure. The recycled pipe can only reach its own pressure.

The above method is for reference only. It is recommended to consult us for more accurate information.

If you have read this article and have any questions, please feel free to contact IFAN. Below is our contact information:

Whatsapp:+86 13373827623

Email:[email protected]