Introduction

In the realm of fluid systems, the brass filter valve stands as a stalwart guardian, tasked with the dual responsibility of regulating flow and ensuring purity. Crafted from robust brass and equipped with intricate filtering mechanisms, this valve plays a pivotal role in maintaining the integrity and efficiency of fluid systems across diverse applications.

Understanding the Structure

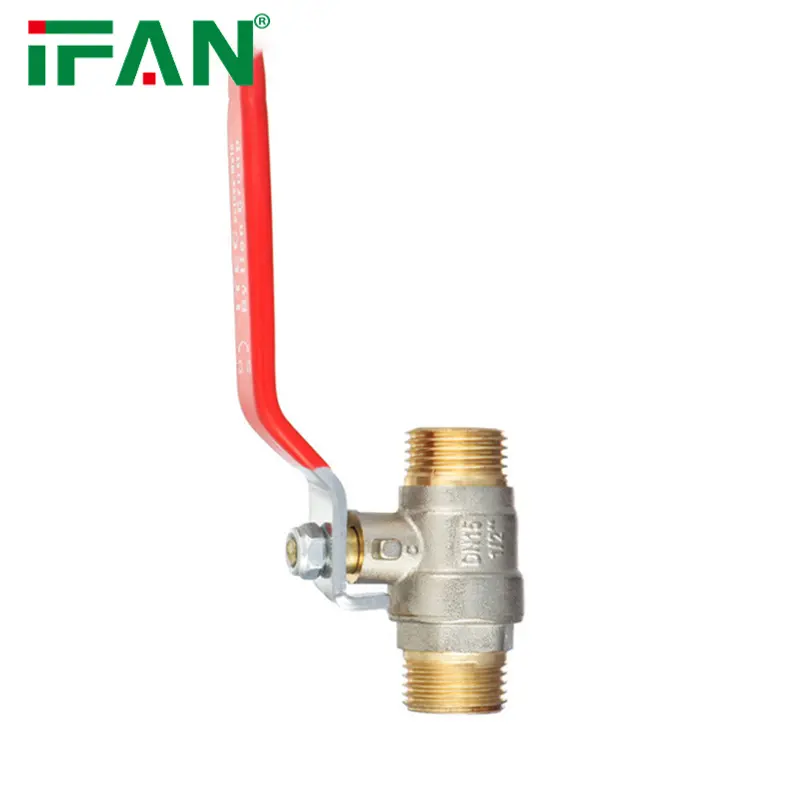

Brass Body

At the heart of the brass filter valves lies its brass body, meticulously crafted to withstand the rigors of operational environments. This sturdy casing provides a reliable foundation, ensuring the structural integrity of the valve even under challenging conditions.

Filtering Element

Nestled within the brass body resides the filtering element, a critical component responsible for purifying the fluid passing through the valve. Typically composed of stainless steel mesh or other porous materials, this element effectively traps impurities, safeguarding downstream components from contamination.

Operational Components

Complementing the robust construction of the brass body and the efficiency of the filtering element are the operational components of the valve. A user-friendly handle or knob facilitates manual operation, allowing for precise control over fluid flow. Meanwhile, strategically positioned inlet and outlet ports ensure seamless integration within the fluid system.

Functionality of Brass Filter Valves

Fluid Regulation

The brass filter valve excels in its primary function of fluid regulation, offering precise control over the flow rate within the system. By adjusting the valve’s position, users can modulate the flow to meet specific requirements, enhancing operational efficiency and system performance.

Impurity Filtration

Simultaneously, the brass filter valve serves as a formidable barrier against impurities that threaten the purity of the fluid. As fluid courses through the valve, the filtering element diligently captures contaminants, ranging from sediments to debris, ensuring that only pristine fluid traverses downstream components.

Step-by-Step Guide to Using Brass Filter Valves

Step 1: Inspection

Prior to installation, conduct a thorough inspection of the brass filter valve to identify any signs of damage or irregularities. Addressing these issues preemptively can prevent complications during operation.

Step 2: Preparation

Prepare the fluid system by meticulously cleaning and flushing it to remove any residual debris or contaminants. A clean system minimizes the risk of clogging and optimizes the performance of the brass filter valve.

Step 3: Installation

With the system primed and ready, proceed to install the brass filter valve in the desired location using appropriate fittings and fixtures. Ensure a secure and leak-free connection to maintain system integrity.

Step 4: Connection

Carefully connect the inlet and outlet ports of the valve to their respective sections within the fluid system, ensuring proper alignment and sealing. Tighten connections as necessary to prevent leaks.

Step 5: Adjustment

Utilize the handle or knob provided with the valve to adjust its position and thereby regulate the flow rate according to operational requirements. Exercise caution to achieve the desired flow without compromising system stability.

Step 6: Testing

Initiate the fluid system and observe the performance of the brass filter valve in action. Monitor for any anomalies or irregularities, and make necessary adjustments to optimize functionality.

Step 7: Maintenance

Sustain the efficacy of the brass filter valve through regular maintenance, including periodic inspection and cleaning of the filtering element. Proactive upkeep mitigates the risk of clogging and ensures prolonged service life.

评价

目前还没有评价