Introducation:

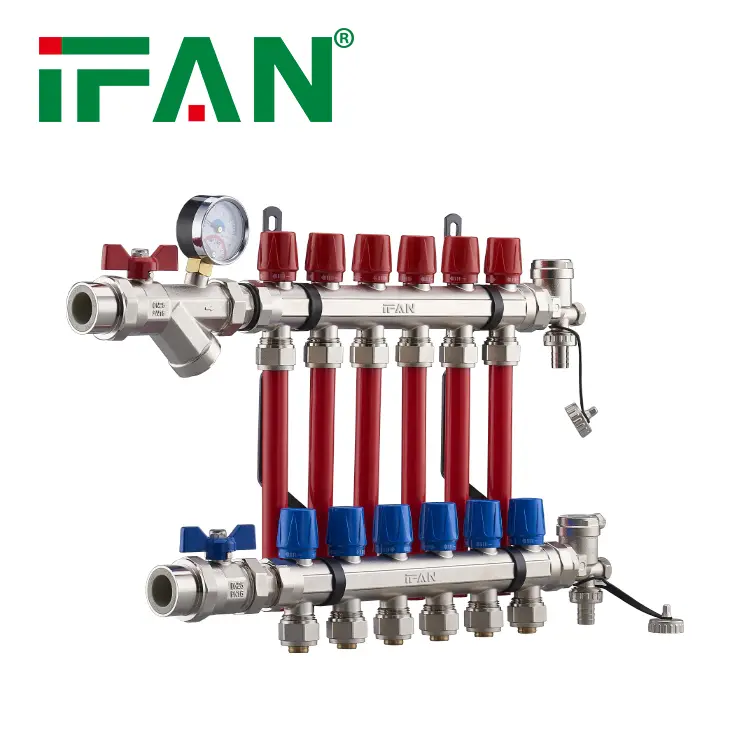

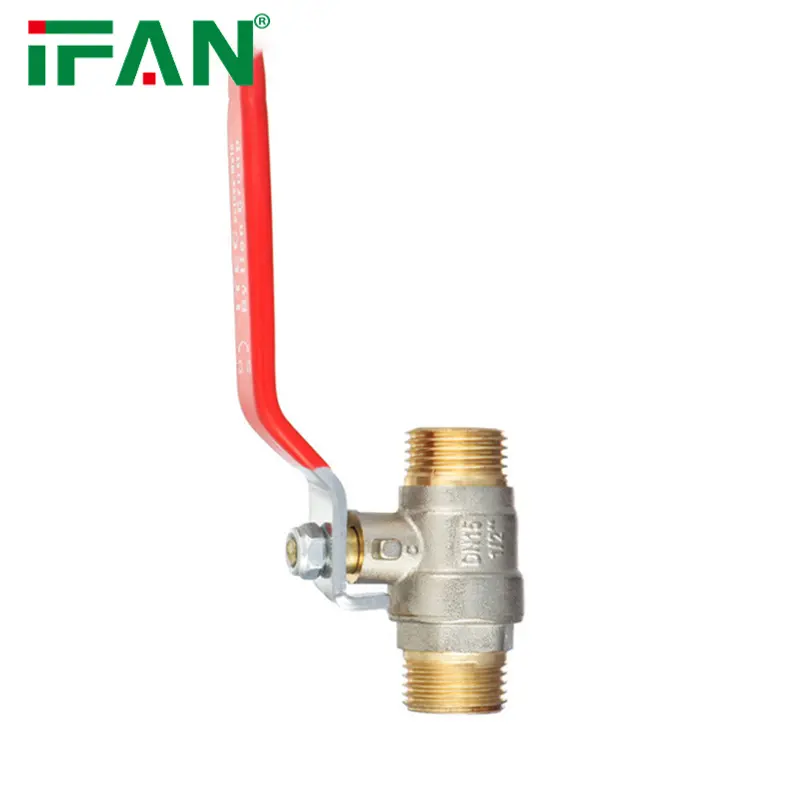

Brass manifold, a fundamental component in fluid distribution systems, serves as the backbone for connecting multiple pipes. Its sturdy construction and reliable performance make it indispensable in various industries where efficient fluid handling is crucial.

Benefits of Brass Manifolds:

Enhances System Durability:

The robust nature of brass manifold ensures long-term durability, making it a cost-effective solution for industries that require consistent performance under demanding conditions. Its resistance to corrosion and high temperatures further contribute to its longevity.

Simplifies Maintenance:

Due to its design simplicity and ease of installation, brass manifold reduces maintenance requirements. This results in decreased downtime and lower maintenance costs, providing significant advantages for industries striving for operational efficiency.

Improves Efficiency:

By facilitating the smooth flow of fluids between different components, brass manifold minimizes pressure drops and energy losses. This optimization of fluid dynamics enhances overall system efficiency, leading to improved performance and reduced energy consumption.

Ensures Seamless Operation:

The precise engineering of brass manifold components ensures leak-free connections and seamless operation. This reliability is essential in critical applications where any interruption in fluid flow can lead to costly downtime and operational issues.

Withstands High Pressures:

Brass manifold’s ability to withstand high pressures makes it suitable for applications where fluid systems operate under extreme conditions. Its strength and resilience ensure safety and stability, even in environments with fluctuating pressure levels.

Applications of Brass Manifolds:

Used in Hydraulic Systems:

In hydraulic systems, brass manifold plays a vital role in regulating the flow of hydraulic fluid to different actuators and components. Its precise control capabilities enable the efficient operation of heavy machinery and equipment, ensuring optimal performance.

Pneumatic Systems Utilization:

Within pneumatic systems, brass manifold serves as a central hub for connecting air lines and controlling air distribution. Its reliable performance and leak-proof connections are essential for maintaining consistent air pressure and flow rates in various pneumatic applications.

Integration in Water Distribution Networks:

Brass manifold is extensively used in water distribution networks to regulate the flow and pressure of water within a system. Its durability and corrosion resistance make it an ideal choice for ensuring reliable and efficient water supply in residential, commercial, and industrial settings.

Essential Component in HVAC Systems:

For heating, ventilation, and air conditioning (HVAC) systems, brass manifold provides the necessary control over the distribution of air, refrigerants, and other fluids. Its precision in managing flow rates and temperatures contributes to the efficient operation of HVAC systems, maintaining comfort levels in diverse environments.

Critical Role in Industrial Machinery:

In industrial machinery and manufacturing processes, brass manifold is integrated into complex systems to regulate fluid flow and pressure. Its versatility and compatibility with various fluids make it indispensable for ensuring the seamless operation of production lines and machinery in diverse industrial sectors.

评价

目前还没有评价