Introduction:

UPVC pipe fittings are widely used in many industries due to their numerous advantages. These fittings come in various standards and sizes to suit different applications. In this article, we will introduce the different types of standard UPVC pipe fitting, the advantages of UPVC pipe fitting, and how to select the right size for your plastic pipes.

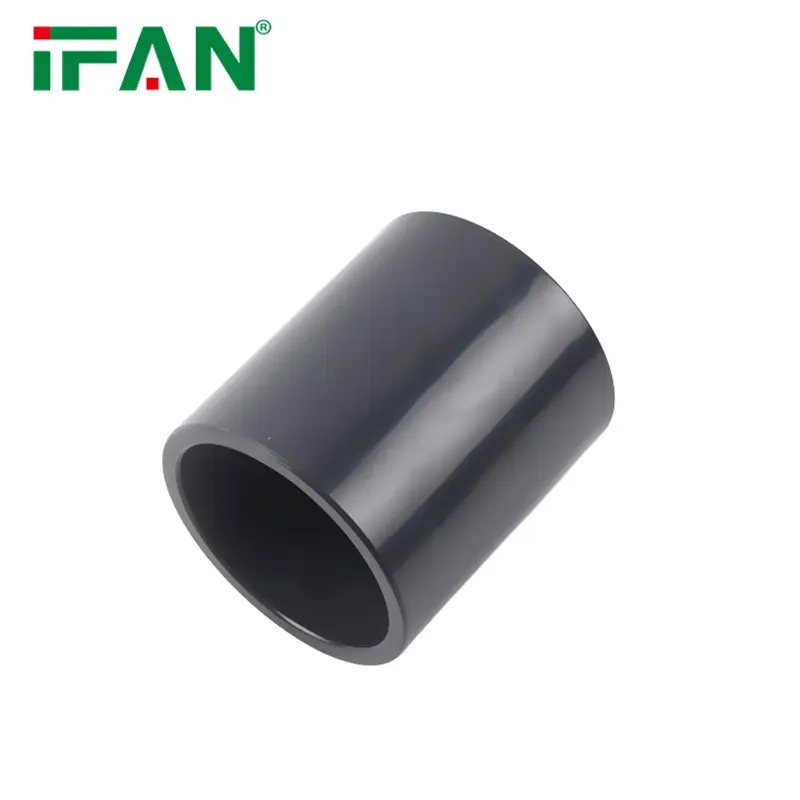

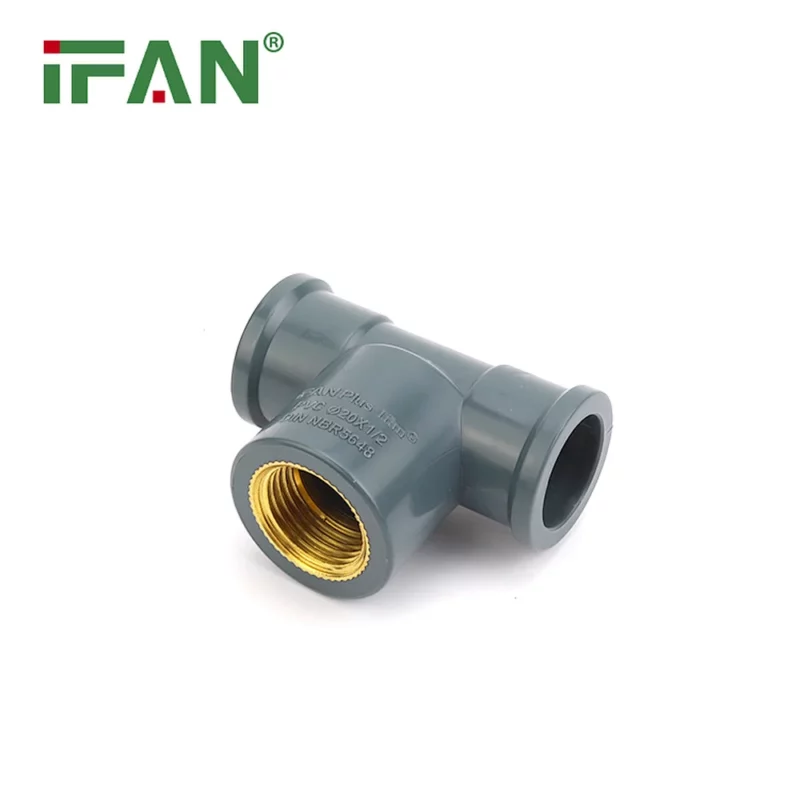

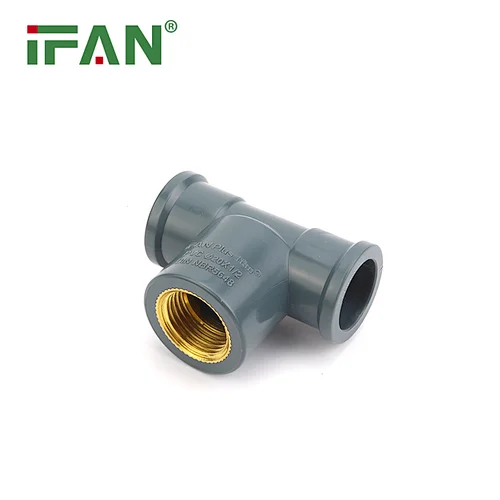

| Product Name |

IFAN UPVC Pipe Fittings |

| Color |

White,Grey,Green Or Customized |

| Size |

1/2″-2″ |

| OEM |

Support |

| Sample |

Free |

| Experience |

30+Years |

| Contact IFAN |

Phone:13373827623 Email:[email protected] |

Detecting the quality of UPVC fittings can be done in a number of ways:

Visual quality inspection

First, the appearance of the UPVC pipe fittings is thoroughly checked. High quality UPVC fittings should be milky and uniform in color. The inner and outer walls are smooth and flat, without bubbles, cracks and obvious uneven defects. At the same time, check whether the mark and identification of the pipe fittings are clear and complete.

Size and geometry check

Use calipers, measuring instruments and other tools to measure the size parameters of UPVC pipe fittings, such as outside diameter, inside diameter, wall thickness, etc. Ensure they comply with national standards and design requirements. In addition, it should also check the pipe bending, cable bending and other geometric dimensions to ensure that it meets the requirements of use.

Mechanical property test

The mechanical properties of UPVC pipe fittings were tested by tensile test, bending test and impact test. Such as tensile strength, breaking strength, impact resistance, etc. These indicators can reflect the bearing capacity and service life of pipe fittings.

Chemical composition analysis

Chemical composition analysis of raw materials for UPVC pipe fittings to understand their composition and content. High-quality UPVC pipe fittings should use high-quality polyvinyl chloride resin as the main raw material. And strictly control the type and dosage of additives.

Thermal stability and thermal aging performance testing

The UPVC pipe fittings are placed in high temperature environment to observe whether deformation, cracking and other phenomena occur. At the same time, the thermal aging test is used to simulate the performance change of the pipe fittings after long-term use, and evaluate its heat resistance and durability.

Pressure resistance test

The internal pressure test of UPVC pipe fittings is carried out to check whether water leakage or rupture occurs under certain pressure. This is an important means to evaluate the bearing capacity of pipe fittings.

Connection mode reliability assessment

The reliability of UPVC pipe fittings, such as socket connection, hot melt connection, etc., is evaluated. Check whether the connection is firm, whether the sealing performance is good, and repeat the test to verify its durability.

Through the above tests, the quality problems of UPVC pipe fittings can be comprehensively evaluated. It should be noted that the relevant standards and specifications should be followed during the testing process. Use appropriate testing tools and methods and be operated by professionals. At the same time, regular quality inspection and maintenance of UPVC pipe fittings. Potential problems can be detected and dealt with in a timely manner to ensure their safe and reliable operation.

评价

目前还没有评价