Introducation:

1.Selecting Materials:

When embarking on making PVC fittings at home, the first step is to carefully select high-quality PVC resin and additives. The PVC resin serves as the primary raw material, while additives like stabilizers and plasticizers enhance the properties of the final product. Stabilizers improve heat and light stability, ensuring longevity, while plasticizers increase flexibility for better performance.

2.Preparing the Mixture:

The key to creating durable PVC fittings lies in preparing a well-blended mixture of PVC resin and additives. This involves meticulous attention to detail to achieve a consistent compound. Through thorough mixing in a high-speed mixer, the PVC resin and additives are homogenized, ensuring uniform distribution of components.

3.Heating and Melting:

Subsequent to mixing the PVC resin and additives, the mixture undergoes a heating process in an extruder. Gradually increasing the temperature, the PVC blend melts and reaches the desired viscosity. This molten PVC state is crucial for the subsequent molding process, allowing for easy shaping and forming.

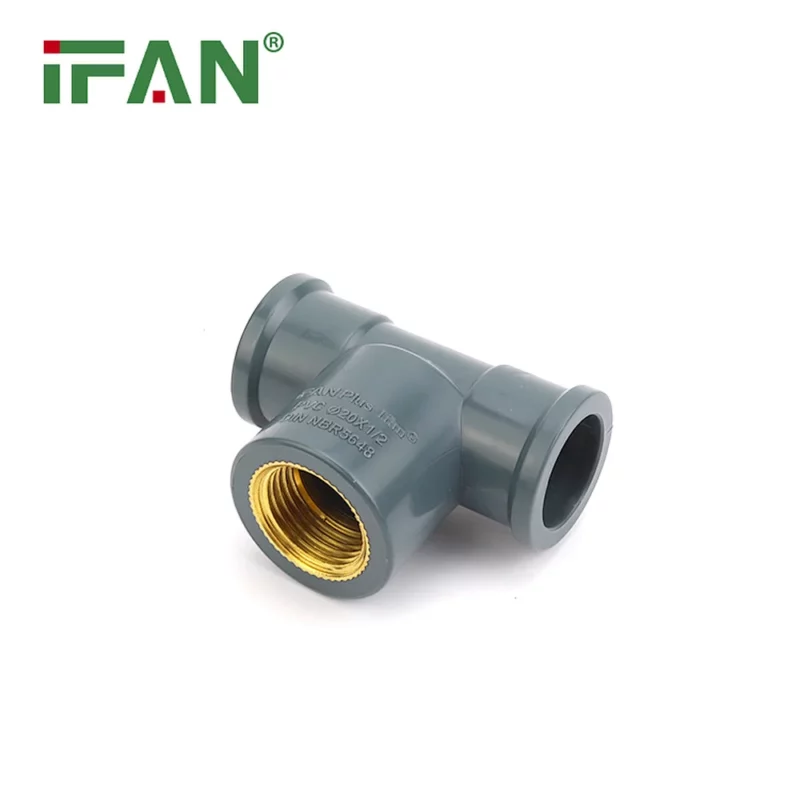

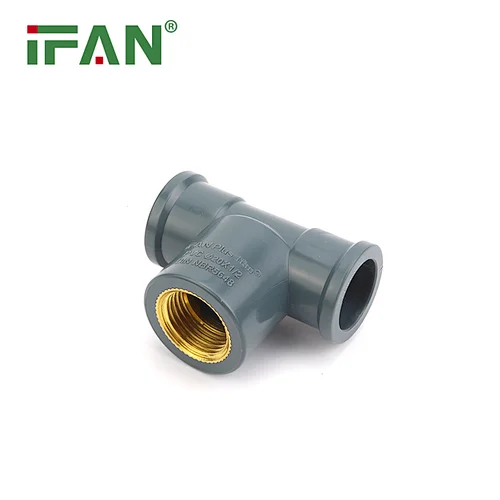

4.Molding Process:

The melted PVC blend is then injected into a mold cavity under high pressure to take on the desired shape of the fitting. The mold’s design plays a critical role in determining the final look and functionality of the PVC fitting. Precision in mold design ensures accurate results, with sharp edges and smooth surfaces reflecting craftsmanship.

5.Cooling and Solidifying:

After the molten PVC blend has been injected into the mold cavity and shaped into the desired fitting, it undergoes a rapid cooling process to solidify. Proper cooling time management is essential to maintain the fitting’s structural integrity and dimensional accuracy. Efficient cooling channels within the mold aid in quick solidification of the PVC.

6.Ejecting the Fitting:

Once the PVC fitting has solidified within the mold, the next step involves ejecting it from the cavity. This process is carried out using either mechanical methods or compressed air to release the fitting smoothly. Ensuring a seamless ejection process helps preserve the integrity of the PVC fitting.

7.Trimming and Finishing:

Following the ejection of the PVC fitting from the mold, any excess material or imperfections are addressed through trimming and deburring processes. Trimming removes flash, the excess material that forms along the parting line of the mold, while deburring smoothens out any rough edges. Additionally, sanding or polishing may be applied to achieve a flawless surface finish.

8.Quality Control:

Throughout the manufacturing process of PVC fittings, stringent quality control measures are implemented to uphold standards. Dimensional inspections verify key measurements such as inner diameters, wall thickness, and angles, ensuring compliance with specifications. Mechanical tests, including pressure testing and impact resistance assessments, validate the strength and performance of the fittings under operational conditions.

How To Make PVC Fittings At Home:

For individuals interested in creating PVC fittings at home, the process begins with selecting quality materials, followed by meticulous preparation, heating, molding, cooling, ejection, trimming, and finishing. By adhering to proper techniques and quality control measures, DIY enthusiasts can craft custom PVC fittings tailored to their specific needs.

Applications of PVC Pipe Fittings:

PVC pipe fittings find extensive use in plumbing systems for connecting pipes and regulating fluid flow. Their versatility, durability, and affordability make them a preferred choice for various applications, ranging from residential plumbing installations to industrial settings.

Benefits of PVC Fittings:

The advantages of PVC fittings lie in their corrosion resistance, ease of installation, and chemical resilience. PVC fittings can withstand high pressures and temperature fluctuations, making them ideal for diverse environments. Their lightweight nature also contributes to ease of handling and transport during installation.

评价

目前还没有评价