Introducation:

1.Versatile and Durable Material

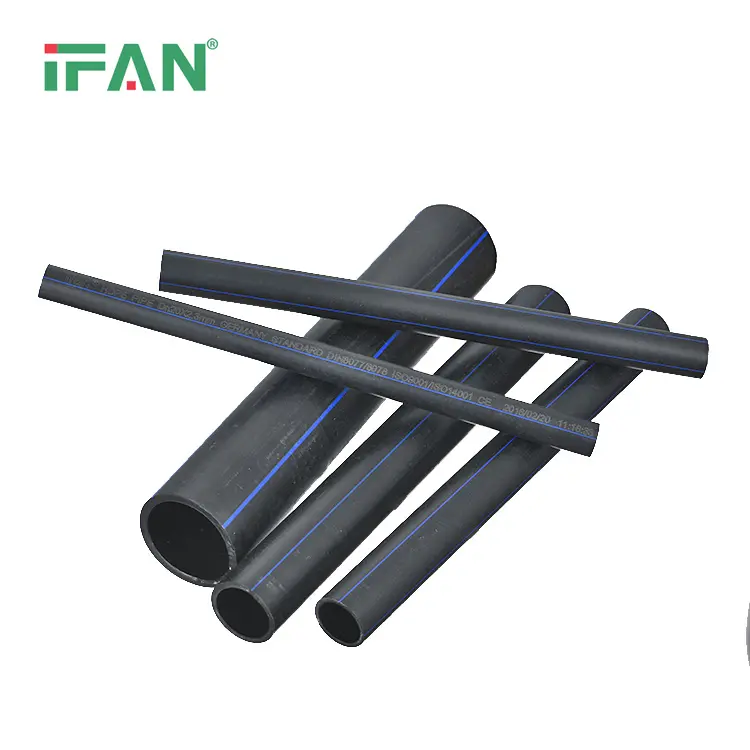

High-density polyethylene (HDPE) is the primary material used in the manufacturing of HDPE pipe fittings. This thermoplastic polymer offers exceptional durability, toughness, and resistance to impact, making it suitable for a wide range of applications. Whether used in underground installations, above-ground systems, or industrial settings, HDPE pipe fittings provide reliable performance and long service life due to their robust material composition.

2.Wide Range of Fitting Types

HDPE pipe fittings come in an extensive array of types and configurations to accommodate diverse plumbing requirements. Elbows facilitate changes in direction, tees enable branching connections, couplings join straight sections, and reducers allow for size transitions. This versatility empowers designers and installers to create complex and customized plumbing networks tailored to specific project needs, ensuring efficient fluid conveyance throughout the system.

3.Corrosion and Chemical Resistance

One of the outstanding properties of HDPE pipe fitting is their remarkable resistance to corrosion and various chemicals. This characteristic makes them well-suited for use in environments where exposure to corrosive substances or aggressive fluids is a concern. Whether in industrial facilities, chemical processing plants, or wastewater treatment facilities, HDPE pipe fittings provide a reliable solution, minimizing the risk of deterioration and ensuring long-term performance in challenging conditions.

4.Ease of Installation and Maintenance

HDPE pipe fittings are designed for ease of installation, with simple joining techniques that streamline the assembly process. The fittings can be connected using heat fusion, electrofusion, or mechanical joining methods, allowing for efficient and cost-effective installation. Additionally, their low maintenance requirements contribute to overall system reliability, reducing the need for frequent inspections and upkeep, and resulting in lower long-term operational costs.

5.Leak-Free Joints and Connections

The design of HDPE pipe fittings incorporates secure joints and connections, significantly reducing the potential for leaks within the plumbing system. When properly installed and joined, HDPE fittings form tight, leak-resistant connections that promote uninterrupted fluid flow. This leak-free attribute is essential for maintaining system efficiency, minimizing water loss, and preventing damage to surrounding structures or environments.

6.Temperature and Pressure Resistance

HDPE pipe fittings exhibit excellent resistance to a wide range of temperatures and pressures, making them suitable for both hot and cold water applications. Their ability to withstand varying operating conditions ensures reliable performance in diverse environments, providing confidence in the integrity of the plumbing system under fluctuating temperature and pressure scenarios.

评价

目前还没有评价