Introducation:

Material Compatibility

Select HDPE fittings that are specifically designed to match the material composition and properties of HDPE pipes. Ensure compatibility to prevent chemical reactions, material degradation, and leakage over time.

Pressure Rating

Consider the operating pressure requirements of your system when choosing HDPE fittings. Opt for fittings with pressure ratings that exceed the maximum anticipated pressure to ensure safety and reliability under all conditions.

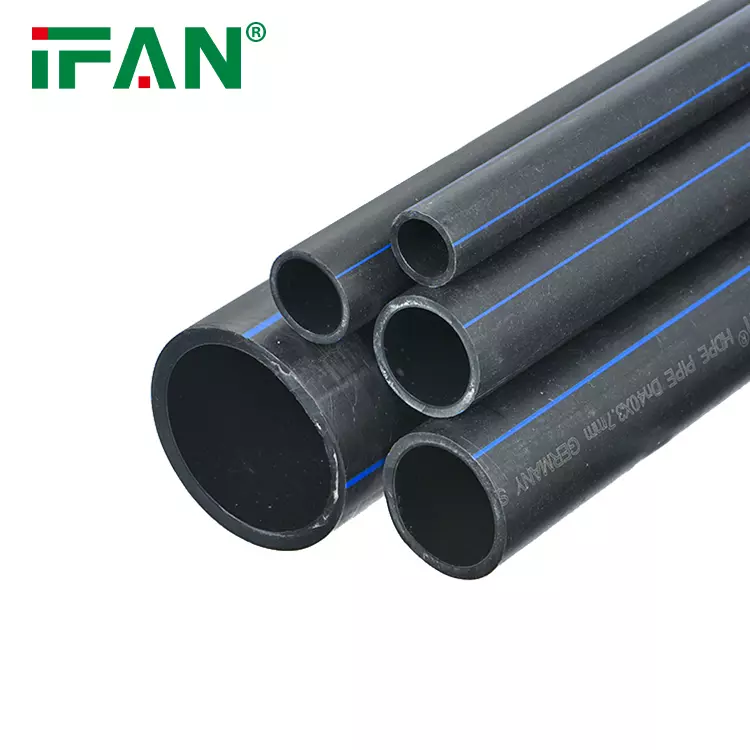

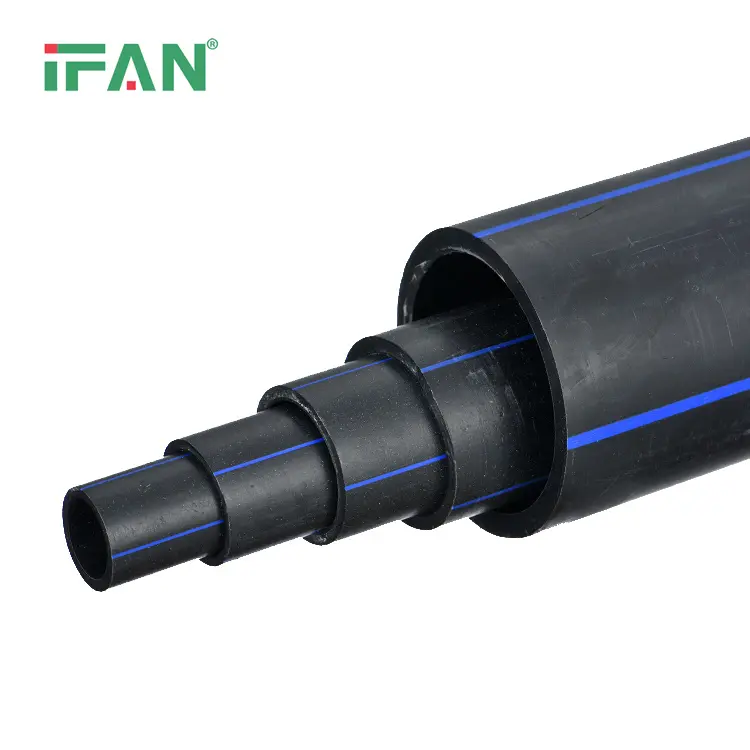

Size and Dimension

Accurately match the size and dimension of HDPE pipe fittings with the corresponding pipes to facilitate proper alignment and sealing. Improper sizing can lead to leaks, pressure drops, and system inefficiencies.

Jointing Methods

Evaluate the most suitable jointing method based on project specifications, installation environment, and budget constraints. Common jointing techniques include butt fusion, electrofusion, socket fusion, and mechanical connections like flanged or threaded fittings.

Environmental Factors

Assess environmental conditions such as temperature fluctuations, exposure to ultraviolet (UV) radiation, soil composition, and potential impact from external elements. Choose HDPE fittings with enhanced UV resistance, corrosion resistance, and durability to withstand harsh environments.

Chemical Resistance

Verify that HDPE fittings possess excellent chemical resistance to withstand exposure to acids, alkalis, solvents, and other corrosive substances commonly found in industrial and chemical processing applications. Consult chemical compatibility charts and material data sheets for guidance.

Installation Techniques

Adhere strictly to manufacturer’s installation guidelines and recommended practices to ensure proper alignment, fusion, and sealing of HDPE fittings. Proper installation techniques minimize the risk of leaks, joint failures, and structural integrity issues.

Inspection and Testing

Conduct thorough visual inspections and pressure tests on HDPE fittings before installation and commissioning. Perform non-destructive testing methods such as ultrasonic testing or dye penetrant inspection to identify any defects, flaws, or irregularities that may compromise performance.

Maintenance Practices

Implement regular maintenance protocols to inspect HDPE fittings for signs of wear, abrasion, chemical degradation, or mechanical damage. Perform routine cleaning, lubrication, and corrosion protection measures to prolong the service life of fittings and ensure system reliability.

评价

目前还没有评价