Types of PPR pipes:

PPR Plastic Pipe are gaining popularity in the plumbing industry due to their high-quality performance and durability. They are made from polypropylene random copolymer. This is a thermoplastic material that is resistant to high temperatures and pressures. The following are several commonly used PPR pipes:

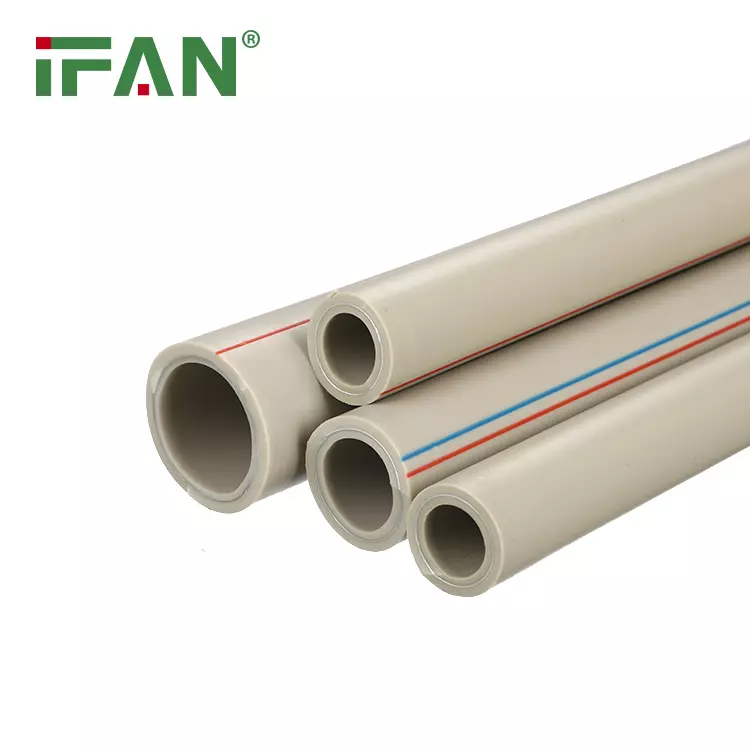

PPR Water Pipe: This is the most common type of PPR pipe used to transport hot and cold water. It has strong corrosion resistance and scale resistance. Ideal for use in residential and commercial buildings.

Hot and cold water PPR pipe: This type of PPR pipe is specially designed for conveying hot and cold water. It is highly flexible and can be easily installed in tight spaces.

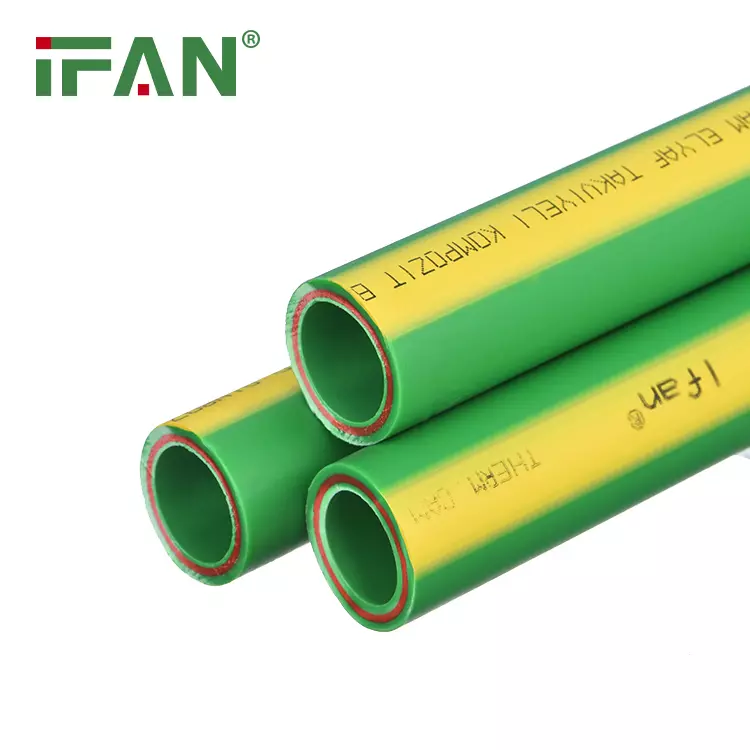

Green PPR Plastic Pipe: This type of PPR pipe is used in residential and commercial buildings to transport potable water. It is highly resistant to chemicals and UV radiation. Ideal for outdoor applications.

Each type of PPR pipe has its own unique features and benefits. It is very important to choose the correct type of PPR pipe for your specific needs. To ensure optimum performance and longevity.

Installation steps:

1. Preparations. First determine the location and length of the pipe. Then determine the connections on the pipes. Including elbows, tees, flanges, etc., and prepare connection tools and welding materials.

2. Cut the pipe. According to the design requirements, use a professional pipe cutter to cut the pipe to the required length. And ensure that the incision is flat and smooth.

3. Pipe cleaning. Before installation, the inside and outside of the pipe should be thoroughly rinsed with clean water. Removes dust, dirt, residue and more.

4. Install the piping. Align the pipes and connecting parts. Make sure they are in the correct position and orientation. Then solder. during welding. The corresponding welding machine and welding materials should be selected according to the materials of the pipes and connectors. And standard welding process. To ensure welding quality.

5. Pipeline testing. After the pipeline installation is completed, the watertightness test of the pipeline should be carried out. Check that the pipe connections are tight. Ensure that the pipe installation quality meets the standard requirements.

The above is the professional installation process of PPR pipe. Need to go through strict operation and testing. Ensure the safety and reliability of the pipe.

In conclusion:

In recent years, PPR pipes have become more and more popular in hot and cold water systems. It’s durable, long-lasting and easy to install. Making it an excellent choice for any plumbing project.

When choosing the right PPR pipe for your needs. There are several factors to consider. The size of the pipe, its intended use, and the quality of the material are all important considerations.

Contact us IFAN

IFAN has 30+ years of experience in the plumbing industry. If you are looking for suppliers of PPR Pipe, please visit our website, you will get the price and other detailed information about ppr. Welcome to contact IFAN, this is our Whatsapp: +86 13373827623

评价

目前还没有评价