Introducation:

What is high density polyethylene?

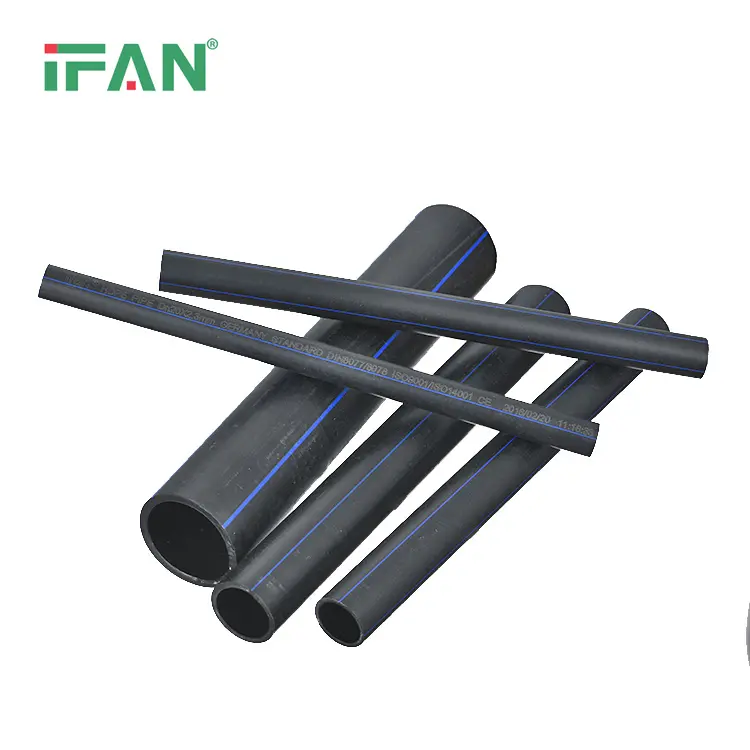

HDPE, or high-density polyethylene, is a petroleum-derived plastic. Known for its impressive strength to density ratio. This means exceptional durability and resistance to moisture, chemicals and UV radiation. These qualities make HDPE a versatile material for a variety of applications. From packaging and pipes to bottles, toys, and even furniture.

Environmental benefits of HDPE:

High Density Polyethylene HDPE pipes and fittings are not only very strong but also resistant to wear and tear. And also a champion of sustainable development. The recyclability of HDPE allows these products to be collected, sorted and repurposed into new applications. This reduces reliance on virgin materials, minimizes waste, and protects valuable natural resources. Additionally, HDPE recycling reduces energy consumption and greenhouse gas emissions compared to virgin plastic production. So, with HDPE pipe and fittings, you get long-lasting performance and environmental responsibility

Durability and longevity:

HDPE is extremely durable and has a long lifespan. Especially in applications such as plumbing and outdoor furniture. Its resistance to corrosion, weathering and degradation ensures products made from HDPE pipes and fittings can withstand harsh environmental conditions without deterioration. This reduces the need for frequent replacement and minimizes waste generation.

Lightweight nature:

Lighter HDPE pipe and fittings require less fuel during transportation. thereby reducing emissions and costs. They are easy to operate and install, further improving energy efficiency and solidifying HDPE’s position as a sustainable material choice.

Chemical resistance:

High-density polyethylene (HDPE) doesn’t just shine with its impressive strength. but also in its commitment to sustainable development. This versatile plastic offers excellent resistance to chemicals, acids and solvents, making it ideal for applications with frequent exposure to such chemicals.

The HDPE recycling process typically involves the following steps:

Collect:

HDPE products are collected from a variety of sources, including homes, businesses and industrial facilities. Collections can be organized by local authorities, recycling centers or private companies.

Sort by:

The collected HDPE products are classified according to their resin type, color and other characteristics. Sorting is critical to ensuring the quality and purity of recycled materials. Because contamination can affect the performance and integrity of the final product.

Clean:

HDPE products are cleaned to remove any dirt, debris or contaminants. Cleaning may include washing, chopping, or grinding materials to prepare them for further processing.

Processing:

The cleaned HDPE material is melted and formed into pellets or flakes. Can be used as raw materials for manufacturing new products. Recycled HDPE pellets can be blended with virgin HDPE or other additives. to achieve specific features and performance requirements.

Manufacturing:

Recycled HDPE pellets are used to produce a variety of products, including bottles, containers, pipes, and more. The manufacturing process may vary depending on the desired end product. But it usually involves molding, extrusion or injection molding.

Usage:

Products made from recycled HDPE once manufactured. will be distributed and used like the original product. Recycled HDPE products offer the same performance and functionality. All while reducing the need for new plastic materials and minimizing environmental impact.

评价

目前还没有评价