Introduction

Brass check valves, a staple in fluid control systems, play a crucial role in maintaining the unidirectional flow of fluids. Crafted from high-quality brass, these valves offer robustness and reliability in diverse applications.

Installation Guide

1.Choose correct size valve: Select a check valve that matches the diameter of your pipes to ensure a snug fit and optimal performance.

2.Ensure pipe alignment: Before installation. Check the alignment of the pipes to ensure they are properly aligned for seamless connection with the valve.

3.Apply thread sealant: Use a high-quality thread sealant to prevent leaks and ensure a tight seal between the valve and the pipes.

4.Tighten securely: Once the valve is in place, tighten the connections securely to prevent any movement or potential leaks.

Usage Instructions

1.Install vertically: For optimal performance, install the brass check valve in a vertical orientation to ensure proper flow control.

2.Ensure proper flow direction: Check the arrow on the valve body to ensure it is installed in the correct direction for the intended flow of fluid.

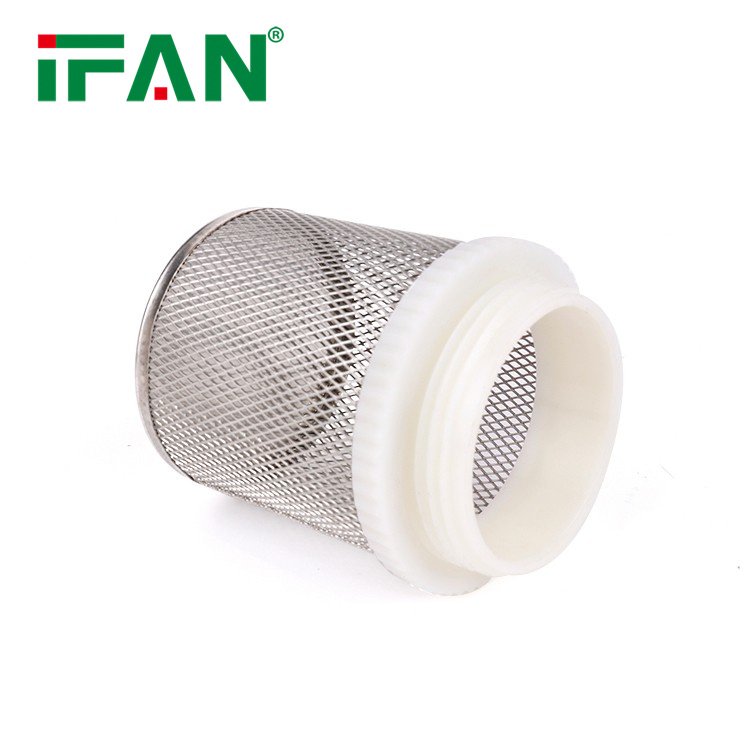

3.Regularly inspect for debris: Periodically inspect the valve for any debris or sediment buildup that could affect its performance, and clean as needed to maintain smooth operation.

4.Replace if damaged: If the valve becomes damaged or shows signs of wear. Such as leaks or corrosion, replace it promptly to prevent further issues and ensure continued functionality.

Benefits of Brass

Brass check valves offer several advantages over other materials, including:

Durability: Brass is known for its strength and resilience, making it ideal for use in demanding environments.

Corrosion resistance: Brass is highly resistant to corrosion, ensuring longevity and reliability even in harsh conditions.

Compatibility: Brass is compatible with a wide range of fluids, making it suitable for use with various applications and industries.

Maintenance Tips

To keep your brass check valve in top condition, follow these maintenance tips:

Clean regularly: Remove any dirt, debris, or buildup from the valve to prevent clogs and ensure smooth operation.

Inspect for leaks: Regularly check the valve for any signs of leaks or damage, such as dripping or corrosion. And address any issues promptly.

Replace worn parts promptly: If any components of the valve show signs of wear or damage, such as seals or gaskets, replace them promptly to prevent leaks and ensure continued performance.

评价

目前还没有评价